Mining the Future: How Innovation Keeps Redefining the Comstock

Part 4 of the Comstock Chronicle Series: “From Gold to Green—The Evolution of the Comstock”

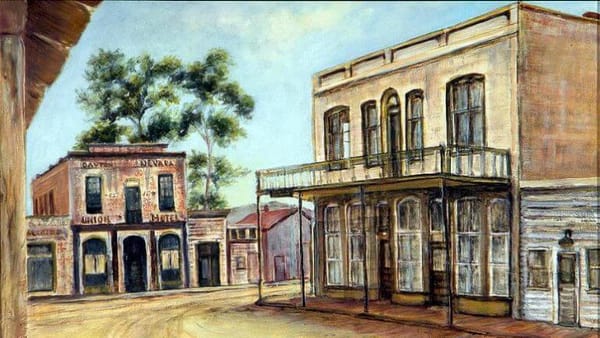

Long before Silicon Valley became synonymous with innovation, Virginia City already was.

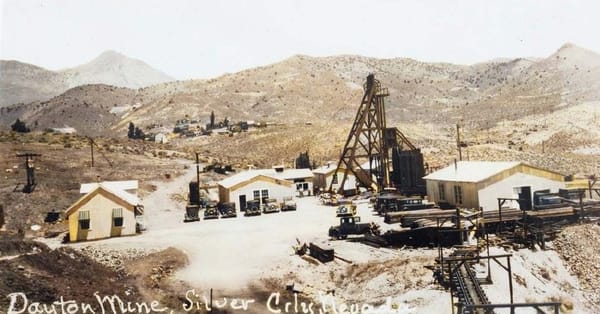

In the 1860s, the Comstock geologies forced miners and engineers to invent solutions the world had never seen. Square-set timbering was developed here to hold back collapsing ground. Industrial-scale hoists, pumps, and milling systems were designed not in theory, but out of necessity. The Comstock mines didn’t just produce silver and gold, it produced ideas that reshaped global mining.

That spirit of innovation never left. It simply evolved.

Today, that same problem-solving mindset lives on through Comstock Mining, a modern subsidiary of Comstock Inc. (NYSE: LODE), operating on the very same ground that once challenged the world’s best engineers. But instead of lantern light and guesswork, today’s tools are data, modeling, and precision.

Modern mining on the Comstock looks very different than it did a century and a half ago. Geological modeling now replaces blind tunneling. Advanced sampling allows teams to understand ore bodies before a shovel ever touches the ground, reducing unnecessary disturbance and improving safety. Risk is managed proactively, with drainage, slope stability, and environmental controls designed into operations from the start.

Yet perhaps the most significant shift is philosophical.

For generations, mining meant going deeper, moving more rock, and pushing farther into the earth. Today, that definition is changing. Modern mining is no longer limited to what lies beneath the ground, but increasingly includes materials that already exist above it, embedded in infrastructure, equipment, and products society has finished using.

This idea, often called urban mining, reflects a broader shift in how resources are valued. Instead of viewing used materials as waste, they are increasingly understood as recoverable deposits, not unlike the ore bodies that first drew miners to the Comstock. The skills required to unlock that value are familiar ones: material characterization, separation, recovery, and responsible processing.

For Comstock, this shift feels less like a departure and more like an evolution. The same expertise developed over decades of traditional mining, understanding complex material systems, designing efficient recovery processes, and minimizing environmental impact, now informs how the company thinks about resource recovery more broadly. Mining, in this modern sense, becomes about how value is recovered, not just where it is found.

That mindset also reshapes how operations are planned on the Comstock itself. Extraction is no longer the end goal, but part of a longer lifecycle that includes reclamation, recovery, separation, repurposing, and reintegration. Each project is evaluated not only for what it produces, but for what it leaves behind, and how materials can continue to circulate rather than be discarded.

In this way, urban mining is not a replacement for traditional mining, but an evolution of it. It represents the next step in a long history of Comstock innovation, applying old knowledge to new challenges. Just as 19th-century engineers redefined mining to meet unprecedented conditions underground, today’s teams are redefining it again to meet the demands of a resource-constrained, environmentally conscious world.

The Comstock has always been a proving ground for new ideas. What’s changing is not the spirit of innovation, but the scope. Mining here no longer ends at the edge of a shaft or the boundary of a claim. It extends into the broader responsibility of how resources are sourced, used, and ultimately recovered.